Produce Packing Automation

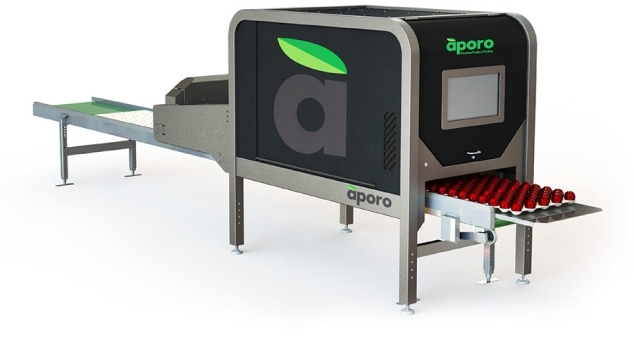

The Aporo II produce packer is the latest iteration of the proven Aporo technology, designed to straddle double packing belts.

Precision Produce Packing.

All Day. Everyday.

Packing fruit into trays remains one of the most labor intensive tasks in the modern packhouse. Global Pac Technologies’ Aporo Produce Packer efficiently, consistently, and reliably pack fruit into trays and then into boxes ready for dispatch.

Our Products

Apple Packer

Aporo II

The Aporo II produce packer is the latest iteration of the proven Aporo technology, designed to straddle double packing belts. Utilising the same proven technology, Aporo II is focused on one of the most labour intensive functions of the modern pack house – getting fruit into tra ...

Case Optimisation Robot

COR

Utilising a unique bundle of cradle and vacuum technology, the VDS Case Optimization Robot (COR) uses an efficient static-location lift and place head to deliver full trays of produce into cases or RDC’s at pace and without damage to your product. ...

Apple Packer

Aporo I

Everything about this machine has been designed with the end user in mind. From its ease of use, rapid deployment and retrofit to existing pack house infrastructure. It is available in configurations for both single and double packing belt packhouse layouts. ...